- Abrasives[1]

- Grinding Machine[2]

- Metal Electroplating Machinery[8]

- Paper Processing Machinery[2]

- Glass Crafts[1]

- Spray Gun[1]

- Mugs[7]

- Plastic Cards[7]

- Badges[6]

- Button Making Machinery[1]

- Transfer Paper[2]

- Transfer Printing[1]

- Printing Inks[1]

- Chemical Auxiliary Agent[1]

- Transfer Film[2]

- Continuous Ink Supply System[6]

- Ink Refill Kits[1]

- Ink Cartridges[3]

- Textile Processing[1]

- Printing Machinery Parts[1]

- Paint & Coating[1]

- Remote Control[2]

- Electrical Plugs & Sockets[4]

- Wireless Networking Equipment[1]

- Other Electronic Components[1]

- Slippers[1]

- Contact Person : Mr. Chuo Alberto

- Company Name : Leader Technology (Shenzhen) Ltd.

- Tel : 86-755-82959676

- Fax : 86-755-82941908

- Address : Guangdong,Shenzhen,6F, 149dong, Jindi Industrial Area, Jindi Yi Rd., Futian Shenzhen Guangdong China

- Country/Region : China

Oil Filter For Spray Plating

Oil Filter and Air Purifier for Spray Plating

- Working Temperature: 0-50C- Exhaust Pressure: 8 (MPa)- Dimension: 200x150x650mm

---

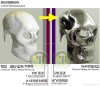

The Chrome Plating system is a kind of high technology spray plating substituting traditional electroplating technology with the distinct characters of no heavy metal and no three discards emitting. It can be applied on the surface of ceramics, plastics, glass, wood, etc. Our tenet is "increase of the product value, promote the development of industry"

The Chrome Plating advantages

Green - no heavy metals, no waste dischargeLow investment and low cost, US$0.75-US$2.80/m2Safety operation – it does not cause any harm to humans or the environmentAutomatic production line is available – we can provide a spray plating production line according to the customer needs.Variety colors - golden yellow, brass color, antique gold, gunmetal, (red, yellow, purple, green and blue), etc.Recycling - spraying plastic products, can be discarded after the crushing, recycling and reuseWide range material application - a variety of substrate materials can be sprayed, without restrictions on the volume sizeSmall area or color mixing process available - the color of decorative plating can be done partially; the color mixing process can also be done partially.

Traditional Plating vs. The Chrome Plating Technology

Comparison Items | Traditional Plating | The Chrome Plating ng |

Environmental Protection | Discharge of the three wastes: waste water, waste gas and waste residue which contain heavy metal | No waste discharge No heavy metal |

Equipment Investment | At least US$40000 investment on plating equipment which does not include water treatment equipment | The spray plating machine can be made according to the customer needs. The size can be made from plating individual objects into production line plating |

Manufacturing Cost | US$5.90-US$7.40/m2 | US$0.75-US$2.80/m2 |

Color Choices | Chrome, Nickel color or gold | Variety colors |

Chemical Recycling | no | Yes |

Application Material | Metal, ABS | All kinds of material |

Size and Shape Restriction | restricted | Non-restricted |

Small area or color mixing processing | No available | yes |

Pre-processing application (e.g. apply conductive layers) | needed | No needed |

The complete solution forThe Chrome Platingsolution:

If you are new in the plating field, you may need other equipment to apply the chrome plating on the object. They are listed as below:

Spray Plating Machine x 1unitAir Compression x 1unitAir drying machine x 1unitOil Filter x 2pcsWater Curtain Cabinet x1 unitOven x1 unitOil Filter For Spray Plating

![Spray Chrome Plating System (Spray Plating Machine,environmental protection)100%Guarantee-Standard Model-Silver chrome[JETYOUNG]](http://img.ecbay.xyz/photo/product44/1445380/product-spray-chrome-plating-system-spray-plating-machine-environmental-protection-100-guarantee-standard-model-silver-chrome-jetyoung.jpg)